Xinhe hige-efficient welding equipment V2.0

1、Product introduction

Xinhe high-efficient welding equipment not only reduces the energy consumption during welding, also can effectively lift welding quality as well as the efficiency of welding. Compared to traditional welding technology, The continuous development and

application of high-efficiency welding equipment has largely promoted the further development of welding technology and manufacturing. It provides good technical support for the manufacture of high-end, precision and special equipment.

2、Advantages of high-efficiency welding equipment

Efficiency advantages

The efficient welding equipment can increase the welding efficiency by 0.6 to 1 times in aluminum alloy, carbon steel and other thin plate materials. The equipment can improve the welding quality and reduce the welding defect rate caused by the artificial factors of the welder.

Technical advantages

Xinhe high-efficiency welding equipment occupies a small footprint and can be moved flexibly. It can realize flat welding and other welding processes, Complete high-quality, high-precision rotating shaft or plate parts and other types of workpiece welding work.The surface of the welded product is smooth and the whole has a sense of texture. It can be used without post-processing.

Operational advantages

Xinhe high-efficient welding equipment is easy to learn, flexible and convenient.Compatibles with any automatic equipment, welding robot, etc. , can be used with the original welder.

Environmental advantages

Xinhe high-efficiency welding equipment can be used in high temperature, high pressure and toxic and harmful welding environment. Let the wisdom of welding greatly improved energy and automation, It can stabilize welding quality and improve production efficiency, helps users control costs. Effectively copes with the pain points of difficult recruitment and high cost of welding workers, and helps build full-cycle intelligent productivity.

3、Main technical parameters

Device size 400mm ×150mm ×150mm

Excitation current 0A-50A

Excitation frequency 10Hz-150Hz

power 30W

Rated input voltage 220±10%

4、Product objects

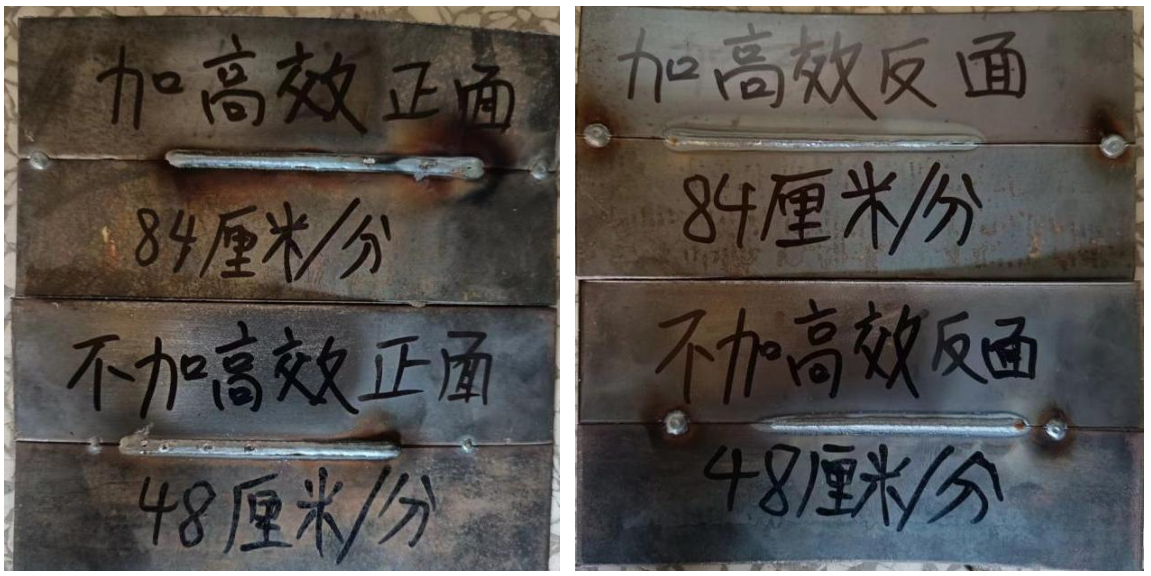

5、Contrast experiment of carbon steel sheet welding

Efficiency comparison

Experimental plates and parameters

Plates:2mm X 50mm X 200mm carbon steel, no Groove, no blunt edge, no clearance

Interface: Docking

Welding Position: flat welding position

Do not use High-efficient welding equipment parameters:

Current: 130A Voltage: 16.3V Speed: 48 cm/min

Use High-efficient welding equipment parameters:

Current: 164A Voltage: 17.2V Speed: 84 cm/min

Conclusion: Use High-efficient welding equipment, in same welding quality without using high speed equipment, Increase welding speed from 48 cm/min to 84 cm/min,about 75% .

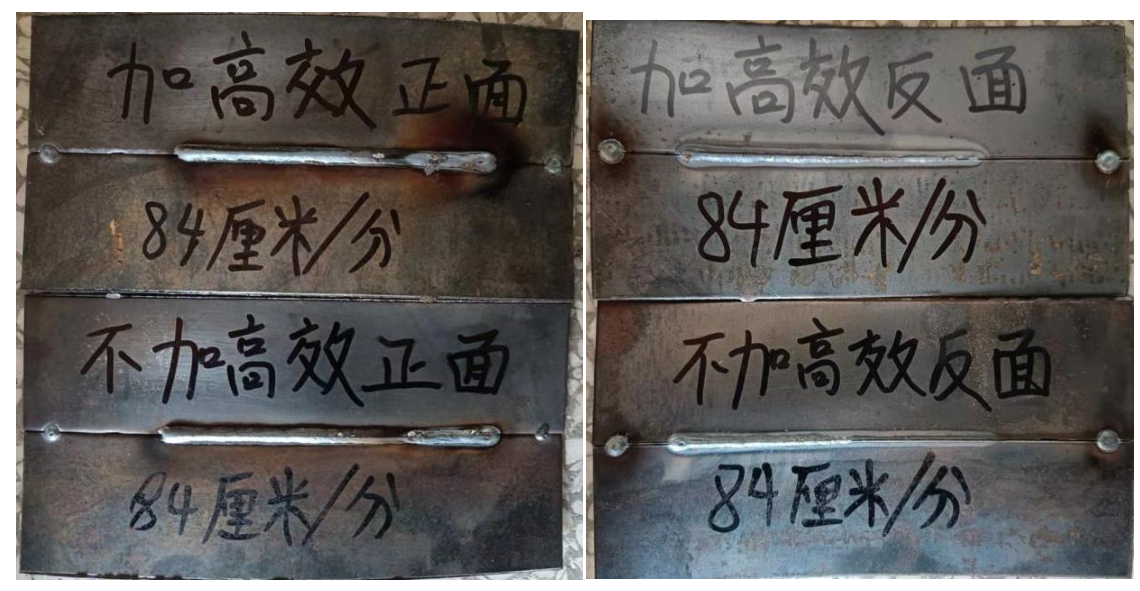

Quality contrast

Experimental plates and parameters

Plates:2mm X 50mm X 200mm carbon steel, no Groove, no blunt edge, no clearance

Interface: Docking

Welding Position: flat welding position

Do not use High-efficient welding equipment parameters:

Current: 164A Voltage: 17.2V Speed: 84 cm/min

Use High-efficient welding equipment parameters:

Current: 164A Voltage: 17.2V Speed: 84 cm/min

Conclusion: Use High-efficient welding equipment, In the case of high-speed welding,The welding quality is better than that without using high-efficiency equipment and meets the quality requirements. Without efficient equipment,Nearly half of the welds have no penetration and the quality is not up to the requirement.

【Return】